Calibration of Body Sensors

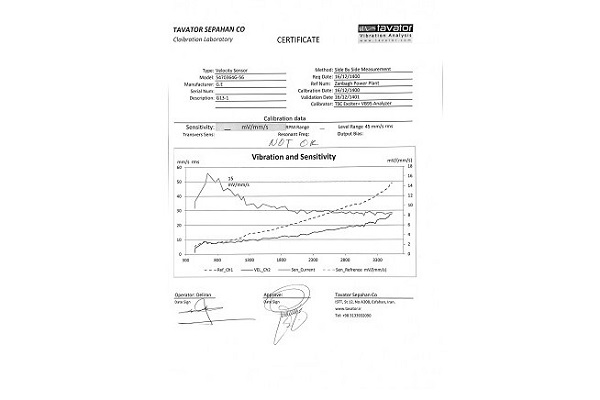

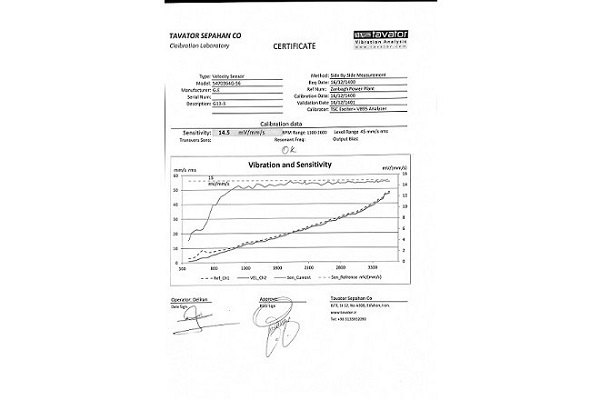

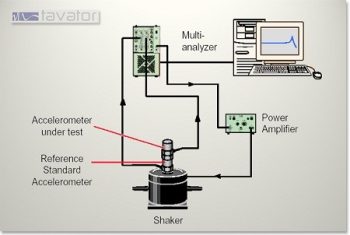

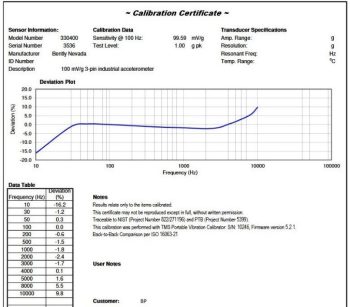

Calibration of body sensors, which includes accelerometers and velocity sensors, is carried out using a shaker and vibration controller. In this test, the frequency response of the sensor is measured for the intended operating frequency range. Typically, these types of sensors do not allow for sensitivity adjustment, meaning that they cannot be calibrated for their defined sensitivity. However, their sensitivity can be measured at different frequencies. The result of the test indicates whether the sensor is acceptable or unacceptable. Additionally, the sensitivity of the sensor is measured and displayed at various frequencies.

Testing Methods

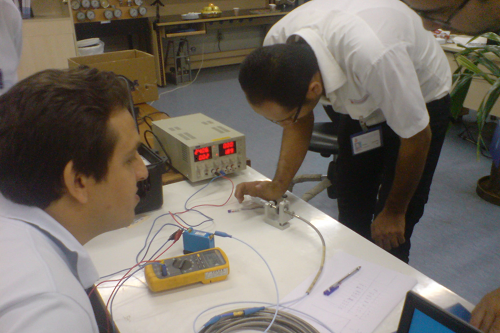

The best method for measuring the sensitivity of these sensors is to install them back-to-back with a designated calibration sensor and use a separate controller, shaker, and analyzer. If a specific calibration sensor is not available, a reliable alternative is to use a measurement from another sensor and a vibrometer.

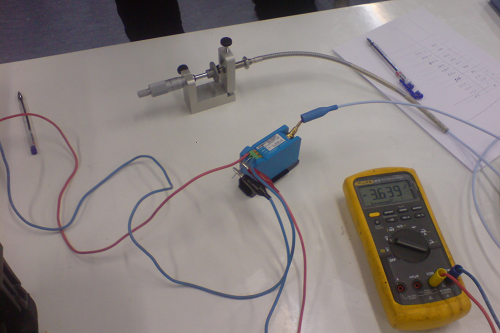

In another method, the reference vibration is measured by the shaker itself, and the output should be measured with a monitor or voltmeter. This method can also be performed on-site and does not require any additional equipment.

Typically, these calibrators have the capability to connect to a computer and can automatically provide confirmation of the calibration results.

Calibration of Non-Contact Sensors – Proximity Sensors

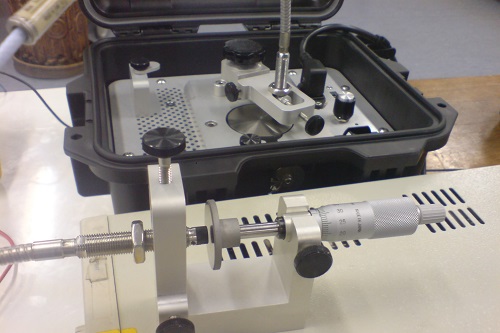

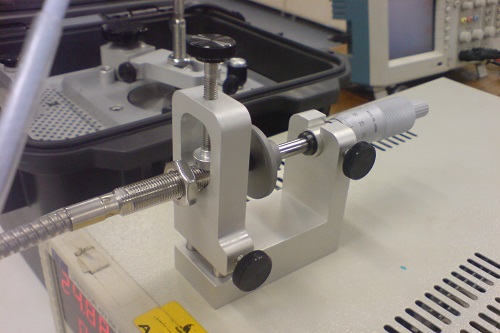

Since proximity sensors provide both DC and AC outputs, the calibration of these sensors includes two parts: static and dynamic testing. The installation of these types of sensors must be done with greater precision compared to contact sensors.

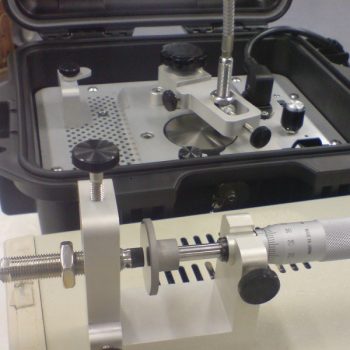

In the static test, the DC output of the sensor is recorded at various distances of the sensor tip from the target (substituting for the shaft) using a voltmeter, and the sensitivity curve of the sensor is plotted and calculated based on these values.

In this plot, the nonlinear regions at both the lower and upper ends of the sensor are also identified.

In the dynamic test, the AC output of the sensor is measured using a vibrometer for the sinusoidal movement of the target plate (substituting for the shaft) at a predetermined amplitude and compared with the original value.

The calibrator for these sensors is commonly known as the TK3 device.

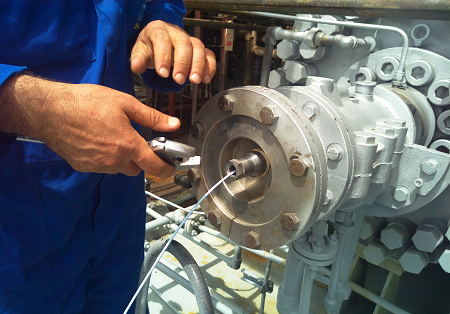

On-Site Calibration – Loop Check

In a warm loop check, the vibration measurement systems of the sensors are disconnected from their installation location and attached to a shaker (for body sensors) or to the TK3 (for proximity sensors). By creating vibrations with a specific frequency and amplitude, the desired value must be read on the control room monitor and compared with the shaker value. Typically, a discrepancy of up to 2% is considered acceptable.

Reference

books

download software

Current seminars

Scientific and research

town of Isfahan

Vibration Training

Guide to training courses

educational calendar

services

condition monitoring

Field Balancing

Shop Balancing

Machinery Alignment

Vibration Labratoary

products

VB95 vibro balancer

Payande software

VM4-96 system

VM4 monitor

VM4-96-p monitor

monitoring software

cabin balance 93

ROD

CAL-401

Stroboscope

BNC box

conectors and cable

![]()