Vibration Condition Monitoring

What is Vibration Condition Monitoring?

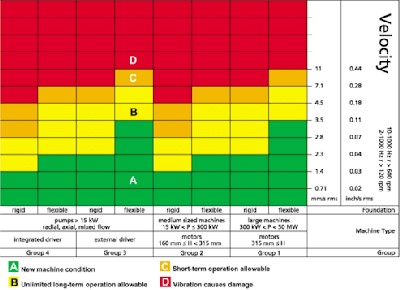

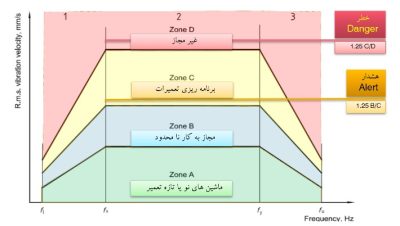

In simple terms, condition monitoring refers to the periodic observation of the behavior of an asset. This asset can be either a rotating equipment or a stationary mechanical or non-mechanical device. Rotating equipment exhibits diverse behaviors, among which vibration behavior is particularly important. Various faults in rotating machines, such as imbalance, misalignment, out-of-center conditions, looseness, gear failure, ball bearing issues, journal bearing problems, belt faults, electrical failures, etc., can all lead to machine vibrations. As long as these faults remain within acceptable tolerance levels, the resultant vibrations will also be considered acceptable. Therefore, standards such as ISO 20816 provide specific thresholds for different machines.

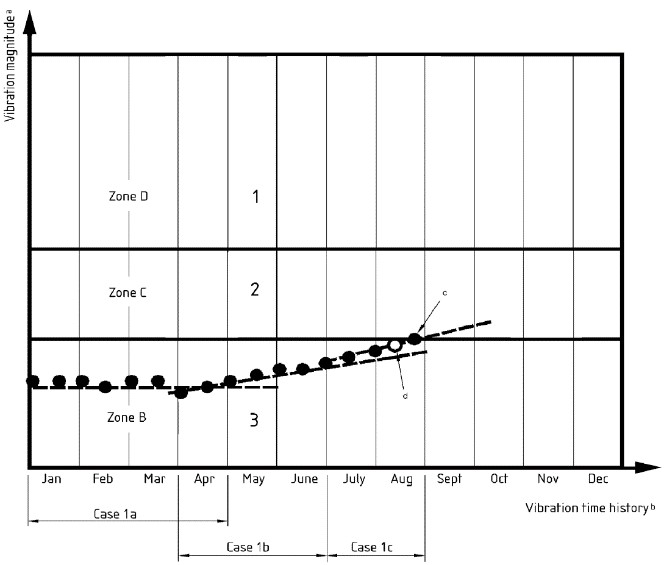

Periodic vibration measurements using various techniques can help us determine the condition of a rotating machine. In a process plant, by measuring and tracking the changes in these readings—such as once a month—we can reveal three key facts:

-

Whether the machine is operating healthily or not.

-

If the machine is in a state of failure, how long it will take for the vibration levels to reach their maximum allowable limits.

-

What the cause of the failure is.

With this information, we can predict the machine’s condition and plan the most efficient maintenance process to achieve the lowest costs, minimal downtime, and the most reliable repair outcomes. This approach is known as Predictive Maintenance (PdM).

Reference

books

download software

Current seminars

Scientific and research

town of Isfahan

Vibration Training

Guide to training courses

educational calendar

services

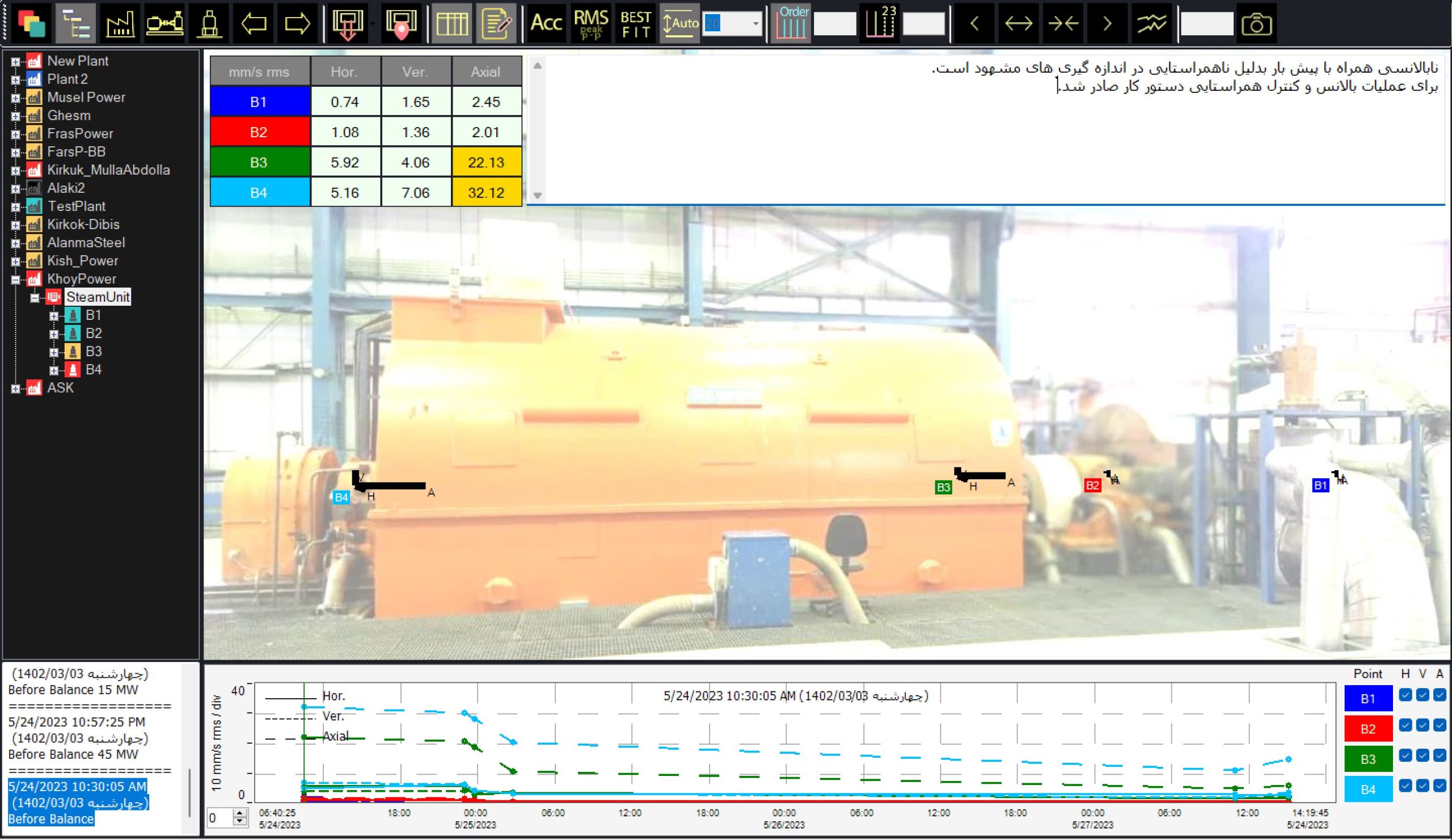

condition monitoring

Field Balancing

Shop Balancing

Machinery Alignment

Vibration Labratoary

products

VB95 vibro balancer

Payande software

VM4-96 system

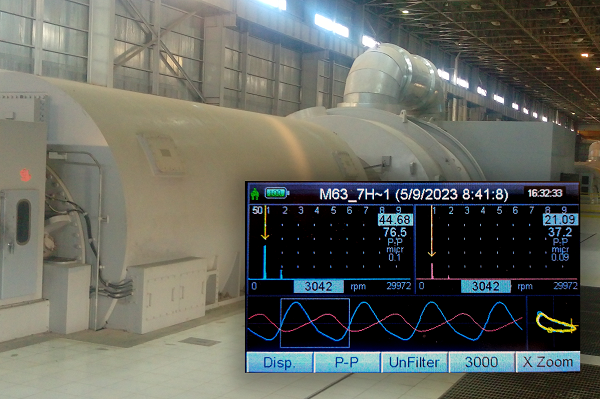

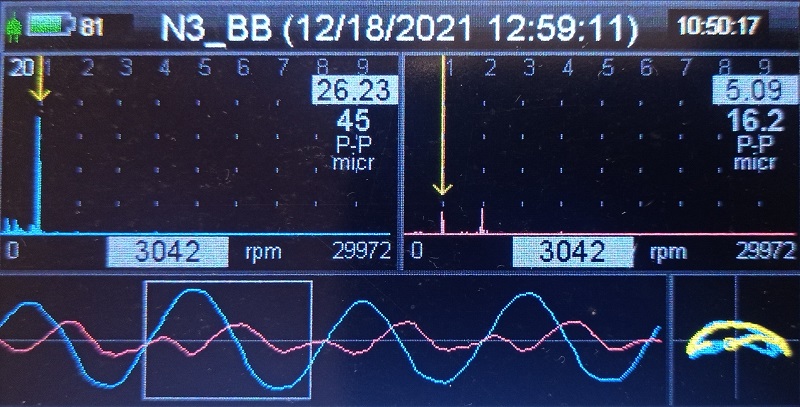

VM4 monitor

VM4-96-p monitor

monitoring software

cabin balance 93

ROD

CAL-401

Stroboscope

BNC box

conectors and cable

![]()