Field Balancing

In practice, any rotary machine can be turned into a balance machine. It only needs to be calibrated. This calibration can be done by measuring the amplitude and phase of the vibration of the bearing or bearings in two primary states and in the state of applying the test mass and performing balance calculations. The test mass is used depending on the number of balance plates in one or two selected plates along the rotor, each of which can be applied in a certain radius and a certain amount of mass. This calibration is valid for a specified rotational speed, which is usually the operating rotational speed of the machine. Performing on-site balancing services, in addition to forces caused by unbalance, balances any type of force with the same frequency as unbalance, including misalignment, shaft bending, off-center, aerodynamic forces, etc. Therefore, in carrying out on-site balance services, it must first be ensured that this vibration is caused by imbalance and not by other forces.

What is imbalance?

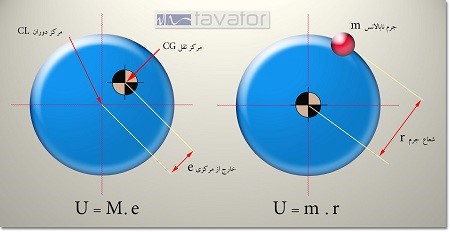

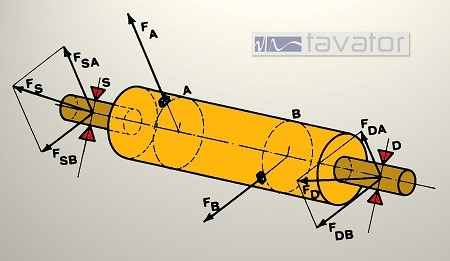

In each plane of the rotor, the imbalance can be considered off-center of the center of gravity of that plane of the rotor relative to the axis of rotation (large mass in a small distance). This imbalance value can be considered equivalent to the mass m in the radius r (small mass at a large distance) and the balance mass can be installed in front of it or the same amount can be subtracted from that place so that the balance operation takes place.

The number of balance sheets

The number of plates that should be selected as the balance plate is different depending on the type of rotor. Based on this, the types of balance can be defined as follows:

Rigid rotor balance – operating speed is lower than the first natural frequency of the rotor.

Single page balance

Two page balance

Multi-page balance

Flexible rotor balance – operating speed is higher than the first natural frequency of the rotor.

Approximation with rigid rotors

Modal balance (balance in vacuum)

The effect of imbalance force in causing vibration of each bearing

In the balancing operation, the effect of the unbalance force of each plate (near and far plate) on the vibration of each bearing (far and near bearing) is measured and the correction weights of the other two selected plates are calculated in such a way that their result is the initial unbalance force neutralize This method is called the influence coefficient method. This method is used in all balance equipment in place today.

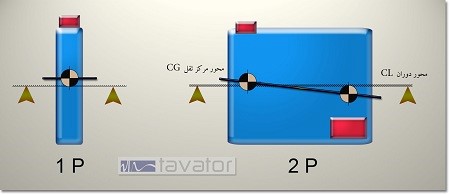

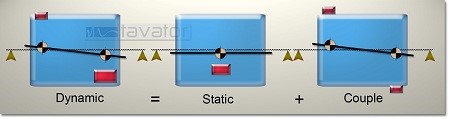

Static and dynamic balance (static couple)

Each single-plane balance can be considered as a static balance and its amount and location can be identified and corrected by static methods by evaluating the gravitational effect of imbalance. But in high-speed or heavy rotors, due to the effects of friction resistance, etc., it is not possible to accurately evaluate this. In this case, it is necessary to dynamically balance the rotor by measuring the effect of centrifugal force.

Unbalances of two plates up cannot be balanced by a static method and it is necessary to balance the rotor by measuring the effect of the unbalance force which can be the vibration of the rotor supports.

Each two-plane imbalance is a dynamic imbalance that consists of two components: couple imbalance and static imbalance. A couple unbalance consists of two identical unbalances but with a 180 degree difference in direction and in two planes far from each other.

In cases where a dynamic unbalance is balanced by a static method, only its static unbalance component is corrected and its couple unbalance remains. In this case, usually the vibration of the two bearings holding the rotor has a phase difference of 180 degrees.

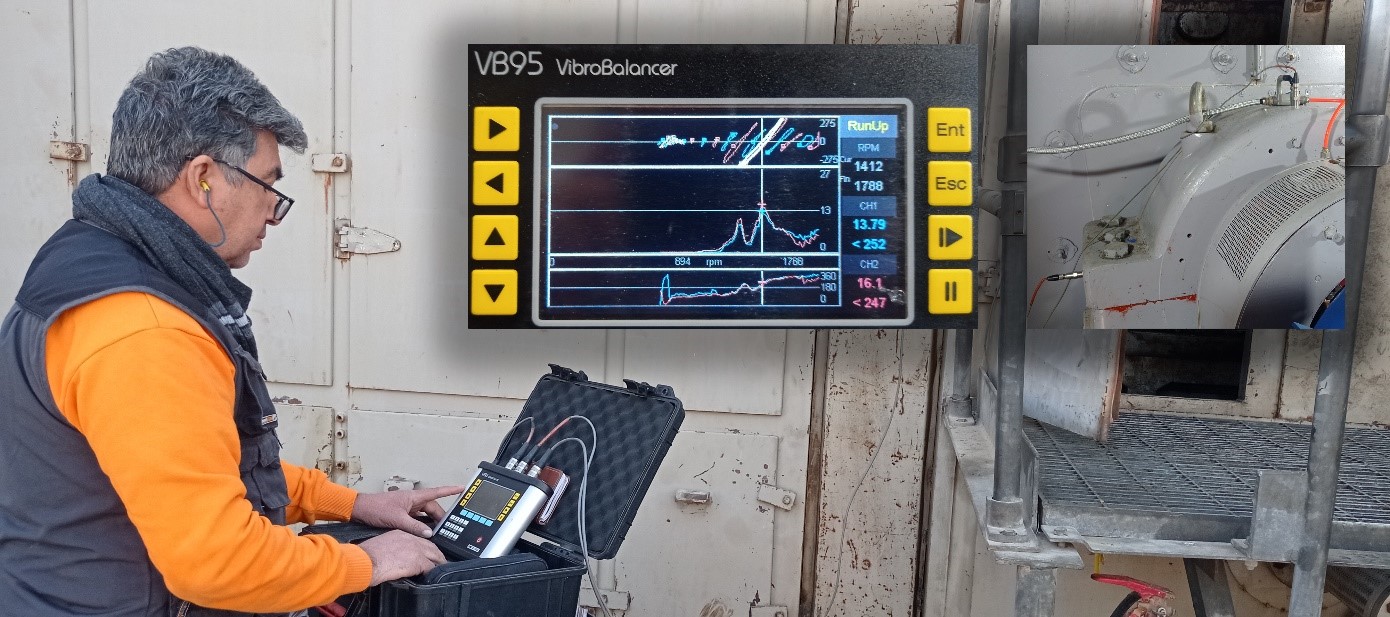

Unbalance response and balance calculations

In a portable balancer, amplitude and phase can be measured by analog and digital methods. In today’s modern equipment, the use of advanced microprocessors, in addition to providing the possibility of obtaining more accurate amplitude and phase values by digital methods, the possibility of performing calculations and displaying values and subsequent processing for vector analysis, storage, graphic displays, information transfer to Computers and .. have been provided and the work of balance has become much easier. But the familiarity of the balance expert with drawing methods and their use even when he has advanced balancers in many cases makes the work of balance easier and faster. In addition, additional advanced techniques allow the user to further investigate imbalance conditions. Therefore, expertise and experience in balance operations is a basic requirement.

Balancing in place is a straightforward and relatively simple procedure under normal circumstances, but in many cases special considerations may need to be taken into account which require more experience. Especially in heavy and high-speed rotors, the dynamic behavior of the rotor and machine assembly has a significant effect on the unbalance response of the rotor.

Reference

books

download software

Current seminars

Scientific and research

town of Isfahan

Vibration Training

Guide to training courses

educational calendar

services

condition monitoring

Field Balancing

Shop Balancing

Machinery Alignment

Vibration Labratoary

products

VB95 vibro balancer

Payande software

VM4-96 system

VM4 monitor

VM4-96-p monitor

monitoring software

cabin balance 93

ROD

CAL-401

Stroboscope

BNC box

conectors and cable

![]()