Machinery Alignment

Misalignment is the second most common cause of vibration in rotating machines. On the other hand, unfortunately, in many factories and for many machines, the issue of misalignment is not considered serious, because in many cases, misalignment does not increase vibration, but has a destructive effect on bearings, couplings, shafts, car bodies, and connections. And it will have a foundation. Therefore, the alignment operation of rotating machines must be done carefully to the required accuracy, which depends on the type of machine, the rotational speed of the machine, and the type of coupling.

Definition of misalignment

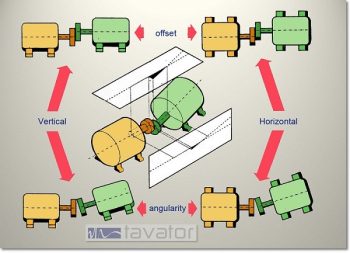

Alignment is the setting of machine bases in the stop mode so that when the machine is working normally, the rotation axes of the coupler machines are on the same axis. Aligning the machines or adjusting the coupling is important, but it is not alignment! In alignment, the goal is to align the two rotation axes of the machines without considering the coupling or its horizontal or vertical alignment. According to the image, each misalignment includes two off-center components (horizontal and vertical) and two angular deviation components (horizontal and vertical). In the alignment operation, all four components must be measured and modified to reduce the total misalignment.

Common methods of alignment

1- Using ingots and fillers:

The simplest method is alignment, which is generally used for simple and low-speed machines. Errors in this method can cause significant vibration problems. In fact, this method is the alignment of two couplings, and any off-center, roughness, diameter difference between the two ends, and coupling machining error will cause errors in this method, and in the best conditions, the accuracy of this method is up to 0.1 mm. This method can be used for simple and low-speed machines and couplings and for the initial alignment of the machine.

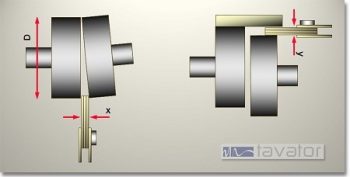

2- Using the indicator clock:

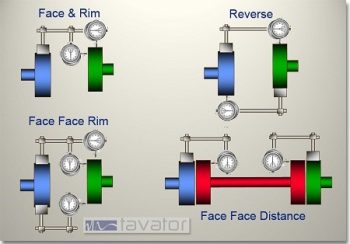

Experienced machine installers still use indicator clocks to install important machines. In using this tool, there are several methods, each of which has its own characteristics. However, these methods can have hidden errors that are still hidden even from experienced eyes. With this tool, in the best cases, up to 0.01 mm accuracy can be achieved, which is enough for the majority of machines. The usual methods of using the indicator clock are shown in the picture.

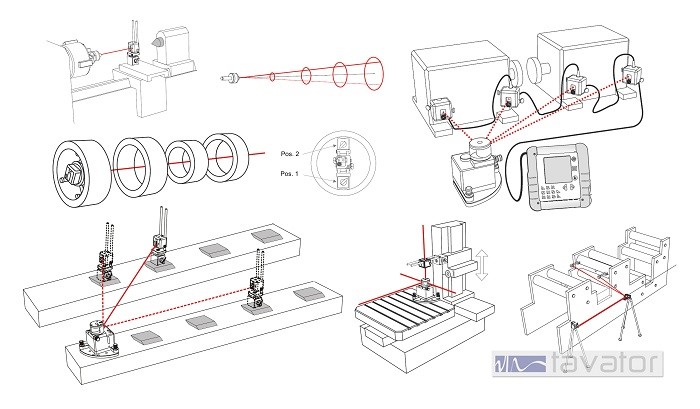

3- Using the laser method:

Laser optics equipment has given the traditional alignment operation speed, accuracy and ease significantly. In the process of repairs and periods of major repairs, repair operations, in addition to having repair costs, the machine downtime will result in the greatest loss of production. The alignment operation can take up a significant part of the machine’s downtime. In addition to increasing accuracy and eliminating the usual errors of traditional methods, laser equipment can reduce the speed of alignment to 1.4 of the usual time.

Today, laser equipment has been developed for various alignments, including the following.

Straightness

Flatness

Alignment of bearings Center of Bearing

Parallelism of axes

Perpendicularity of axes Normality

Centers of the Pointing Direction era

PermAlign online alignment

Other special methods:

In many special machines, special methods may be needed, including:

Using string or wire in aligning the poles

Use of piano wire in aligning bearings with long distances, such as ships or turbines.

Use of precision mapping cameras for alignment in large machines.

Reference

books

download software

Current seminars

Scientific and research

town of Isfahan

Vibration Training

Guide to training courses

educational calendar

services

condition monitoring

Field Balancing

Shop Balancing

Machinery Alignment

Vibration Labratoary

products

VB95 vibro balancer

Payande software

VM4-96 system

VM4 monitor

VM4-96-p monitor

monitoring software

cabin balance 93

ROD

CAL-401

Stroboscope

BNC box

conectors and cable

![]()